Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Home » Gloss, Haze, DOI & Opacity

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

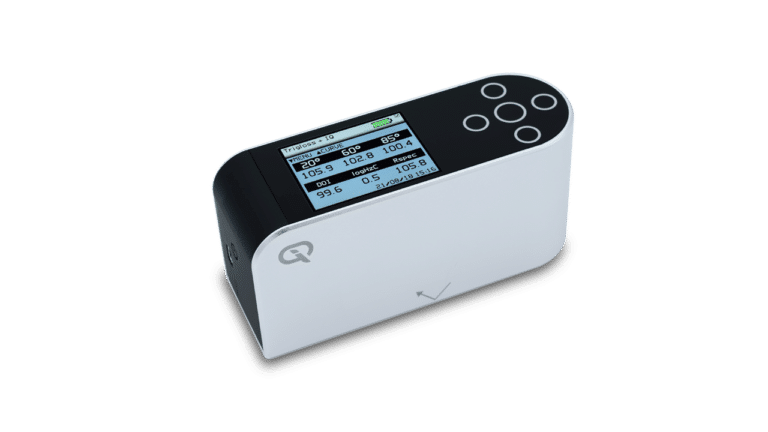

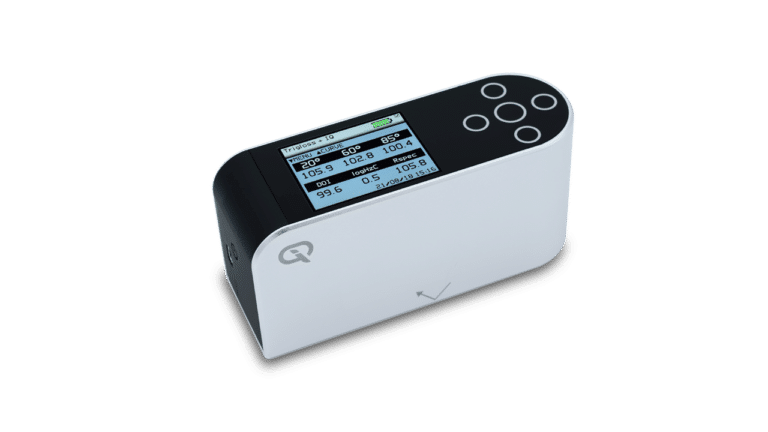

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture