Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

$1,970

The Novo-Gloss 60° glossmeter is suitable for measuring gloss in most applications from matt to high gloss finishes.

This high specification handheld glossmeter is suitable for use in many environments including laboratory and production areas and is the ideal choice for general gloss measurements of a variety of substrates and industry sectors including paints and coatings.

Gloss has been defined as ‘The attribute of surfaces that causes them to have shiny or lustrous, metallic appearance.’

Manufacturers design their products to have maximum appeal: from highly reflective car body panels to glossy household appliances or matt finish automotive interior trim.

This is especially noticeable where parts may be produced by different manufacturers or factories but will be placed adjacent to one another to create the finished product.

Gloss can also be a measure of the quality of the surface, for instance a drop in the gloss of a coated surface may indicate problems with its cure, leading to other failures such as poor adhesion or lack of protection for the coated surface.

The gloss of a surface can be greatly influenced by a number of factors, for example the smoothness achieved during polishing, the amount and type of coating applied or the quality of the substrate.

It is for these reasons that many manufacturing industries monitor the gloss of their products, from cars, printing and furniture to food, pharmaceuticals and consumer electronics.

It is important therefore that gloss levels are achieved consistently on every product or across different batches of products.

ISO 2813 and ASTM D523 (the most commonly used standards) describe three measurement angles to measure gloss across all surfaces.

Gloss is measured in gloss units (GU) and is traceable to reference standards held at NIST (USA).

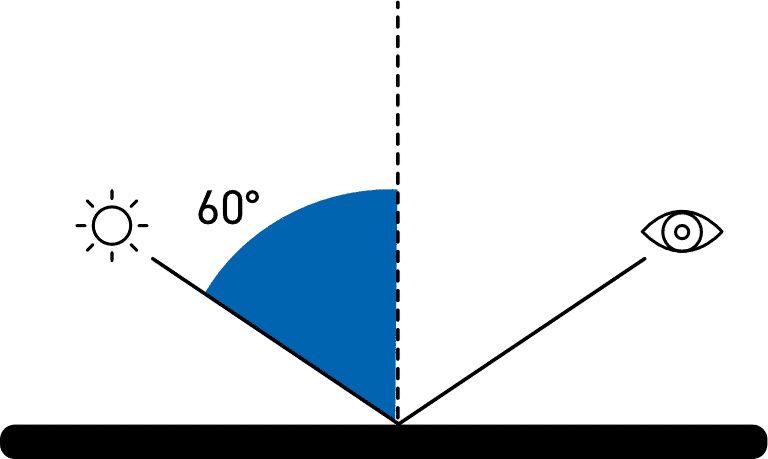

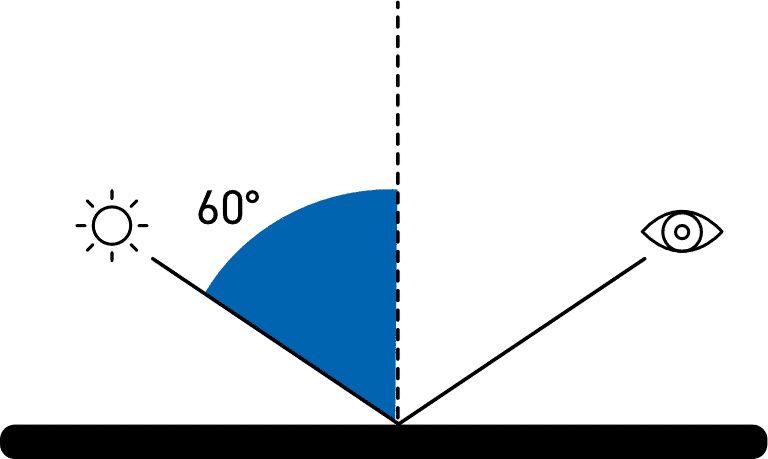

All gloss levels can be measured using the standard measurement angle of 60°. This is used as the reference angle with the complimentary angles of 85° and 20° often used for low and high gloss levels respectively.

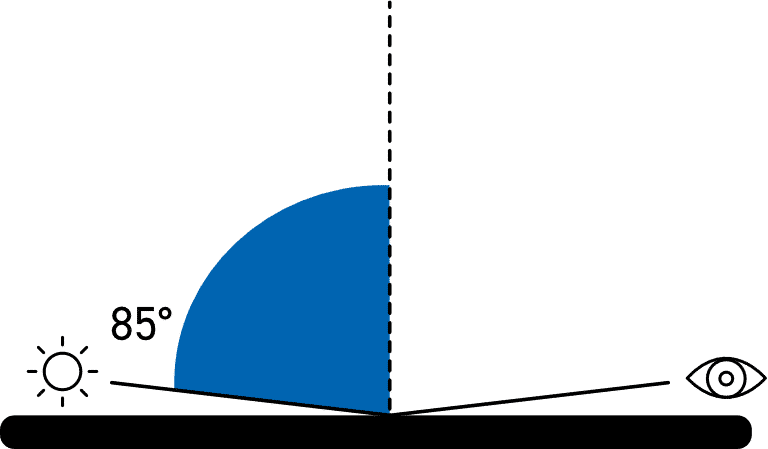

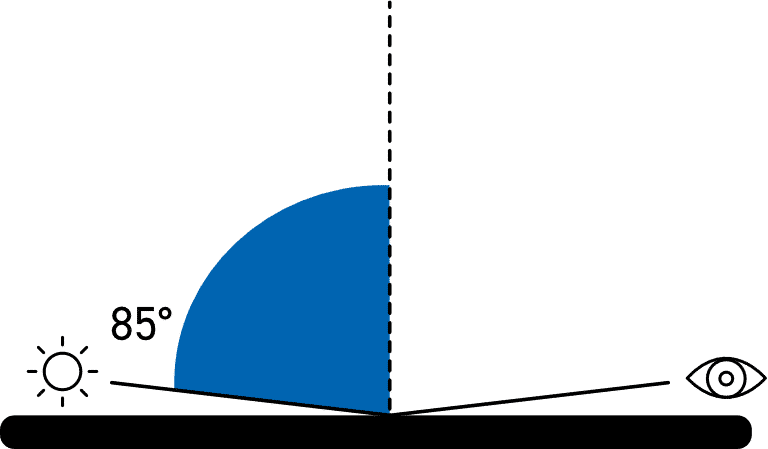

For improved resolution of low gloss a grazing angle of 85° is used to measure the surface. This angle is recommended for surfaces which measure less than 10GU when measured at 60°.

This angle also has a larger measurement spot which will average out differences in the gloss of textured or slightly uneven surfaces.

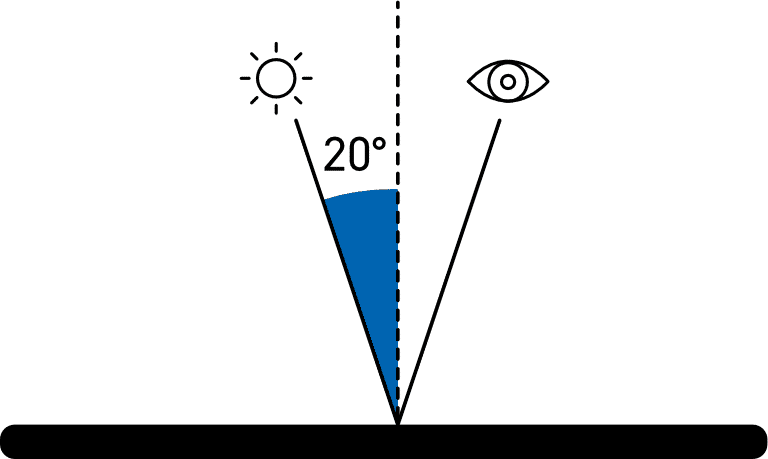

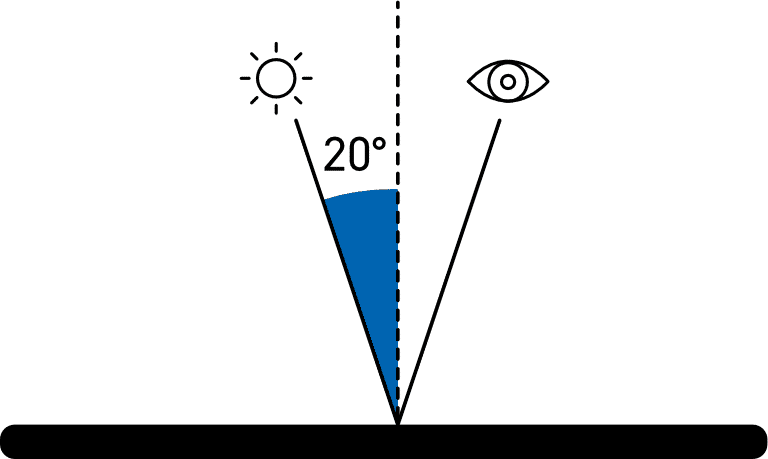

The acute measurement angle of 20° gives improved resolution for high gloss surfaces. Surfaces that measure 70GU and above at the standard angle of 60° are often measured with this geometry.

The 20° angle is more sensitive to haze effects that affect the appearance of a surface.

This measuring angle is in accordance with the ISO 2457 standard for the gloss measurement of plastic films and solid plastic parts as well as according to the standard ASTM C346 for the gloss measurement of ceramics

All gloss levels can be measured using the standard measurement angle of 60°. This is used as the reference angle with the complimentary angles of 85° and 20° often used for low and high gloss levels respectively.

For improved resolution of low gloss a grazing angle of 85° is used to measure the surface. This angle is recommended for surfaces which measure less than 10GU when measured at 60°.

This angle also has a larger measurement spot which will average out differences in the gloss of textured or slightly uneven surfaces.

The acute measurement angle of 20° gives improved resolution for high gloss surfaces. Surfaces that measure 70GU and above at the standard angle of 60° are often measured with this geometry.

The 20° angle is more sensitive to haze effects that affect the appearance of a surface.

To quantify haze, distinctness of image, reflected image quality and other surface texturing please consider the Rhopoint IQ.

| Model | 20° Gloss HIGH GLOSS | 45° Gloss SPECIALTY ANGLE | 60° Gloss ALL GLOSS FINISHES | 85° Gloss LOW GLOSS FINISHES | Haze ASTM E430 | Haze ASTM D4039 |

|---|---|---|---|---|---|---|

| Novo-Gloss 60 | - | - | - | - | - | |

| Novo-Gloss 45 | - | - | - | - | - | |

| Novo-Gloss Trio | - | - | - | |||

| Novo-Gloss 20/60/85 with Haze | - |

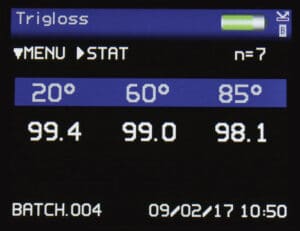

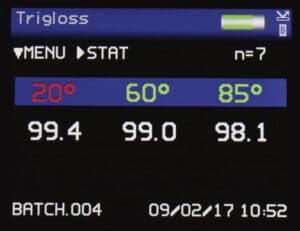

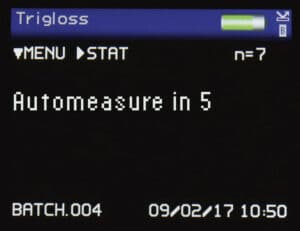

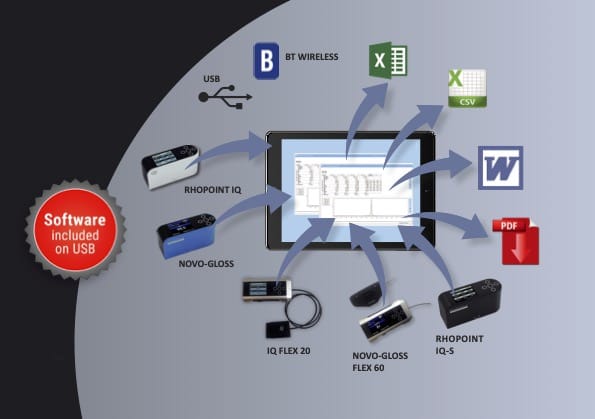

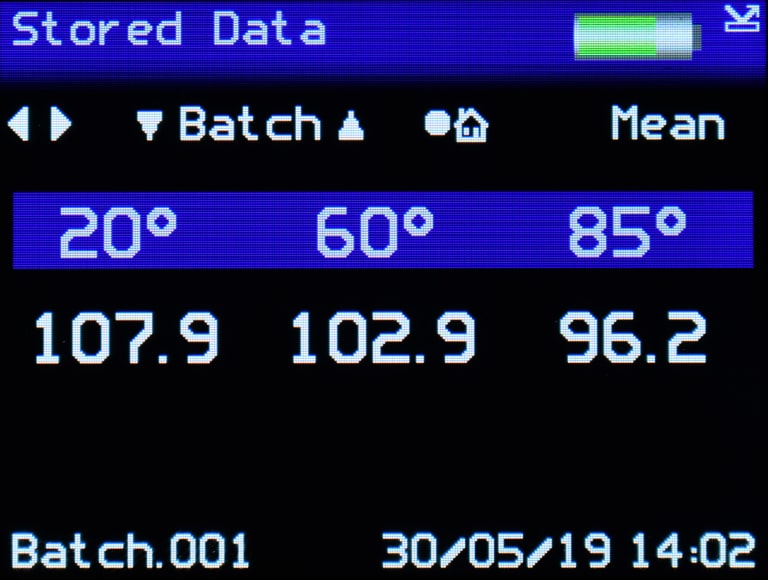

Simultaneous measurement of all parameters in GU or % reflectivity, date and time stamped.

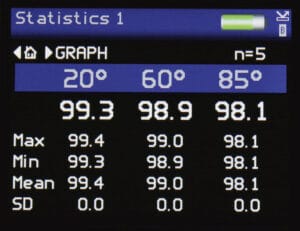

Displays full statistics for the readings in the current batch.

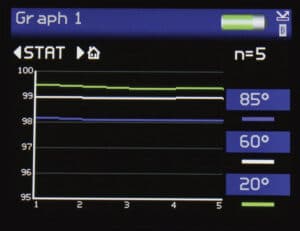

Graphical reporting for quick trend analysis.

Pass / fail parameters can be defined for instant identification of non-conformances.

Automatic measurements at pre-defined intervals for easy checking of large surface areas.

User definable batch names and batch sizes for quicker and more efficient reporting.

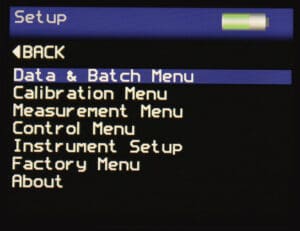

USB connection to PC instantly recognises the device as a drive location which facilitates the quick transfer of .CSV files using Windows Explorer or similar.

Instantly transmit measured readings directly to programs such as MS Excel on your PC / tablet to greatly simplify the reporting process.

The included software provides an easy means to measure, import and compare data and export the measurements into several other file formats, e.g. PDF, Excel® or CSV.

| Instrument Information | ||

|---|---|---|

| Battery Type | Rechargeable lithium ion | |

| Operation Time | 17+ hours | |

| Readings per Charge | 20,000+ | |

| Memory | 8MB, 2,000 readings | |

| Operating Temperature | 15°C - 40°C (60°F - 104°F) | |

| Operating Humidty | Up to 85% (non condensing) | |

| Commodity Code | 9027 5000 | |

| Dimension & Weights | ||

|---|---|---|

| Dimensions | 65mm (H) x 140mm (W) x 50mm (D) | |

| Instrument Weight | 390g | |

| Packed Weight | 1.6kg | |

| Packed Dimensions | 110mm (H) x 280mm (W) x 220mm (D) | |

| Order Codes | ||

|---|---|---|

| Novo-Gloss 60 | A4000-008.2 | |

| Novo-Gloss Trio 20/60/85 | A4000-006.2 | |

| Novo-Gloss 20/60/85 with Haze | A4000-009.2 | |

| Novo-Gloss 45 | A4000-011.2 | |

| Mirror Gloss Calibration Standard | B6000-101.1 | |

| 60° Gloss | ||||||

|---|---|---|---|---|---|---|

| Range | 0 - 10 GU | 10 - 100 GU | 100 - 1000 GU | |||

| Repeatability | 0.1 GU | 0.2 GU | 0.2% | |||

| Reproducibility | 0.2 GU | 0.5 GU | 0.5% * | |||

| Resolution | 0.1 GU | |||||

| Measurement Area | 6mm x 12mm | |||||

| Standards | ISO 2813 | ASTM D523 | ISO 7668 | ASTM D2457 | DIN 67530 | JIS Z 8741 | |||||

* A mirror gloss calibration standard is required to achieve this reproducibility

To ensure accurate and reliable results, Rhopoint Novo-Gloss Instruments are supplied with standards calibrated and certified according to ISO 17025 UKAS.

Rhopoint Americas is a member of the Powder Coating Institute

Free extended 2 year warranty: Requires registration at www.rhopointamericas.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Guaranteed for the life of the instrument.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointamericas.com/help-services/calibration-servicing/ for detailed information.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties