Why measure gloss?

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Board stiffness and crease resistance are important measures that indicate how a finished carton will run on an automated glueing, filling or packaging line.

Substrate manufacturers, printers, converters and any manufacturer who fill or pack products in cartons can use this measurement to optimise production.

QA departments use these instruments to check the running attributes of finished cartons prior to conversion and filling, reducing lost production time from slow running or difficult to convert packaging.

Carton manufacturers and designers can use a Crease and Board Stiffness Tester with a Hanatek Carton Crease Proofer to test different substrate and crease combinations in the laboratory without committing valuable production time.

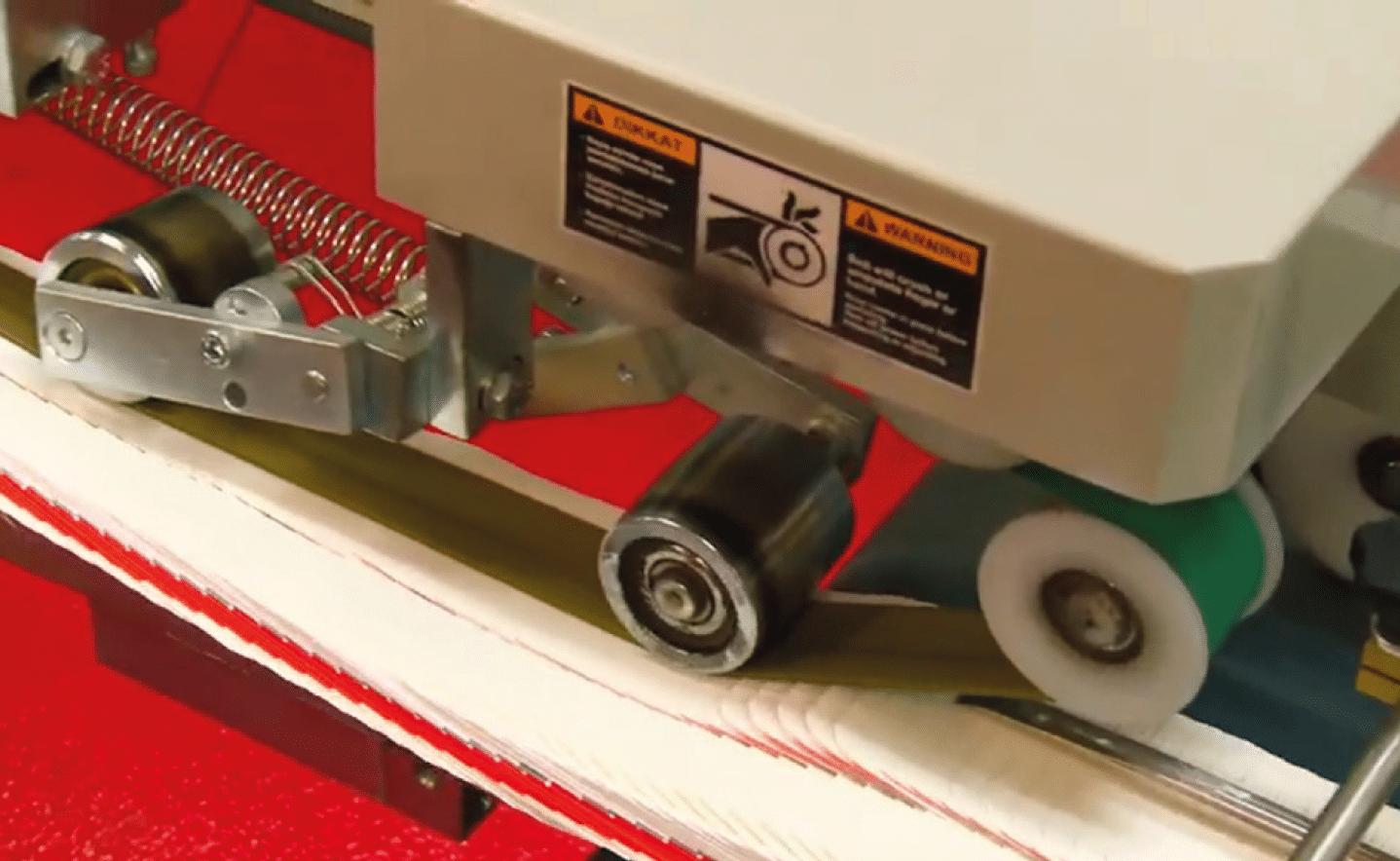

A printed sheet or roll of carton board is die-cut and creased into a preformed carton board blank. This blank is then often glued and erected before being filled on an automated packaging line, these processes all interact mechanically with the blank to convert it into a three dimensional object.

It is also important that the finished material has the required dimensional strength to hold and protect the packaged product.

Board stiffness test and crease resistance testing are important parameters that help determine maximum conversion and packaging speeds, they can also be related to the final dimensional stability of the finished product.

Board stiffness is determined by the physical makeup of the substrate i.e. - its thickness, fibre mix, coating and manufacturing method. It is determined by measuring the resistance of a cut sample to a force applied through a pre-determined angle.

To be most cost effective, it is important this conversion is performed at the maximum speed possible without causing mis-feed and blockages in the process.

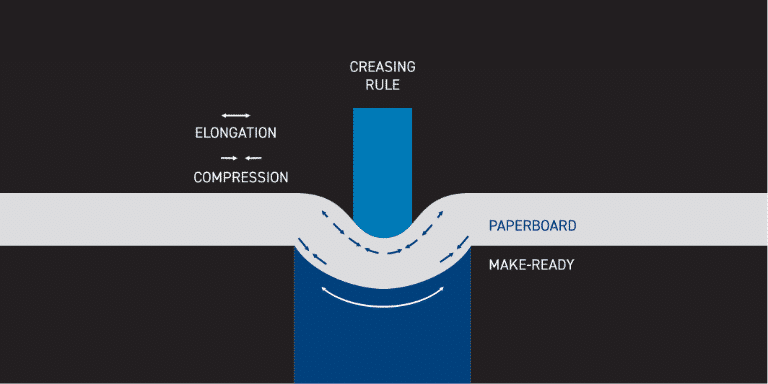

Crease resistance is a similar measure of resistance which is made across a preformed crease in the carton blank.

The Hanatek CBT1 Crease and Board Stiffness Tester gives board manufacturers, printers and packing companies the ability to predict the ‘runability’ of a sample board or finished carton.

15 second measurement delay to eliminate operator variability (according to BS 6965).

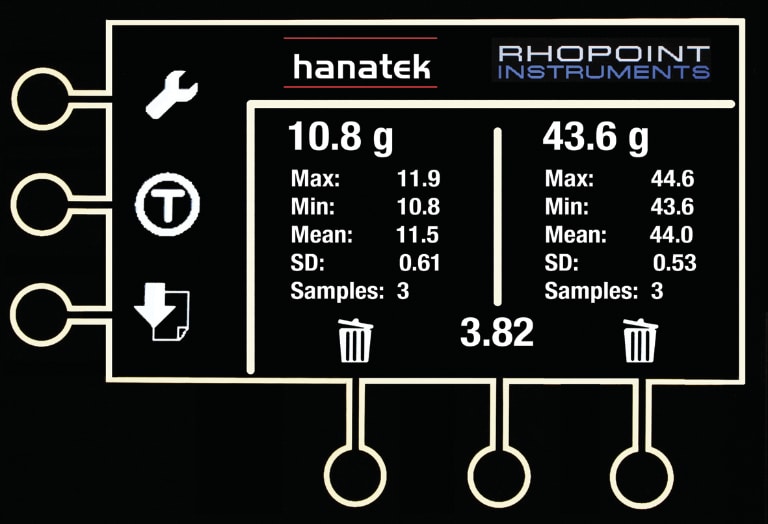

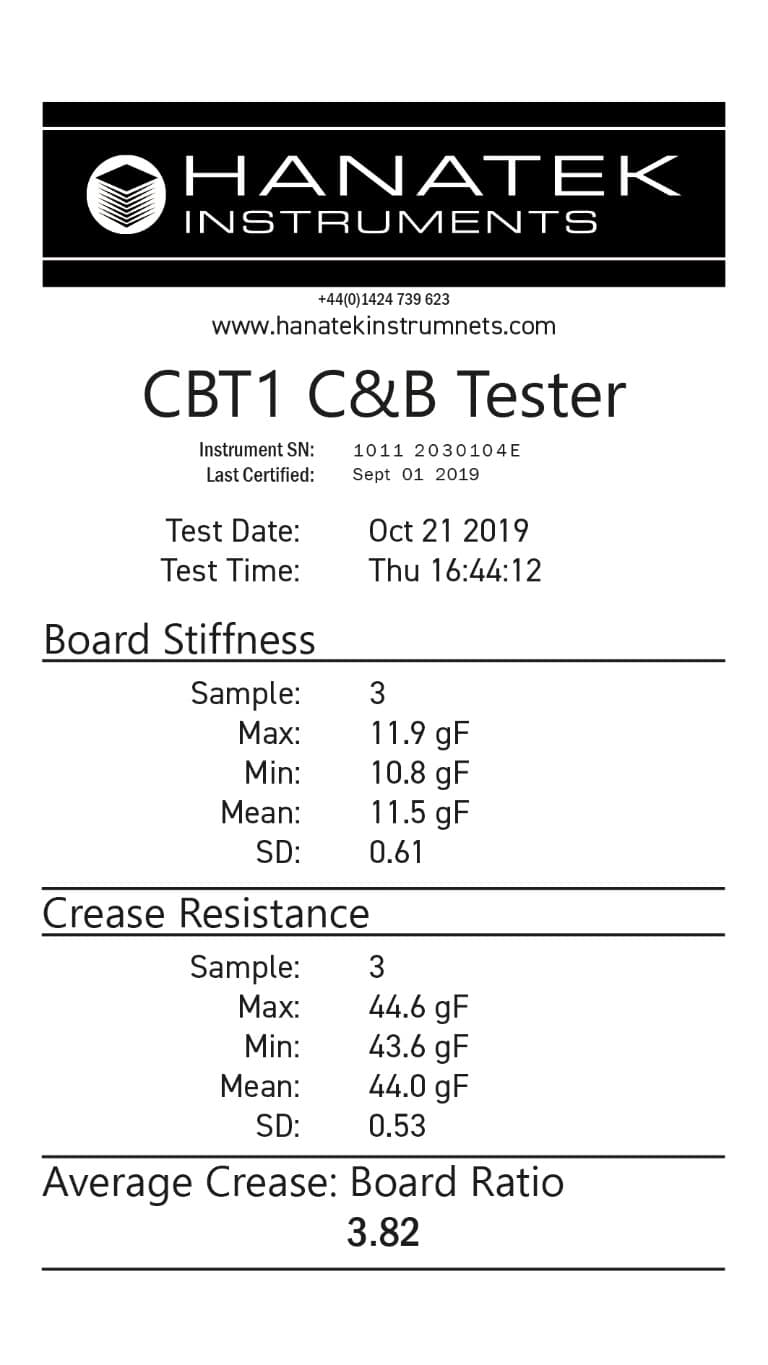

Results calculated and displayed instantly on screen.

Full statistics are displayed for both crease recovery and board stiffness.

Board stiffness is measured on a sample 70 mm x 38mm in size. Board stiffness differs slightly according to whether it is tested with the liner on the side touching the load bar, or on the other side.

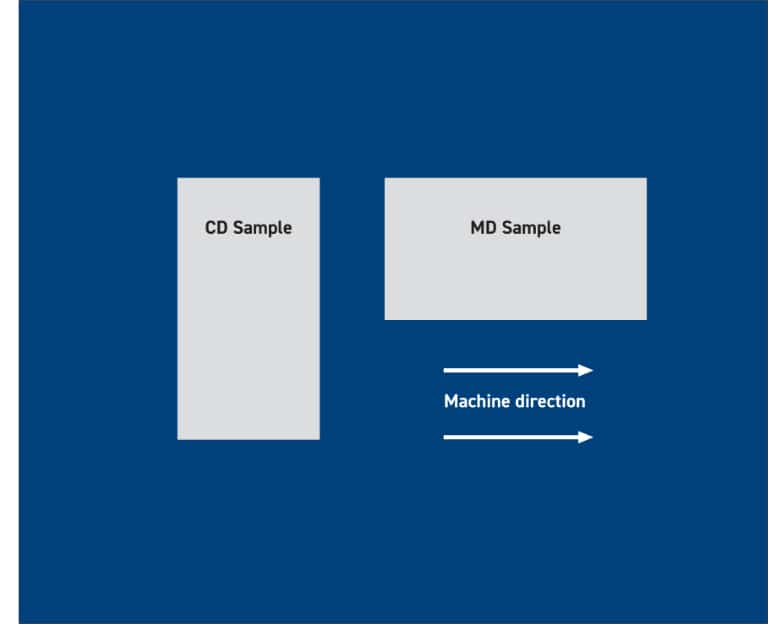

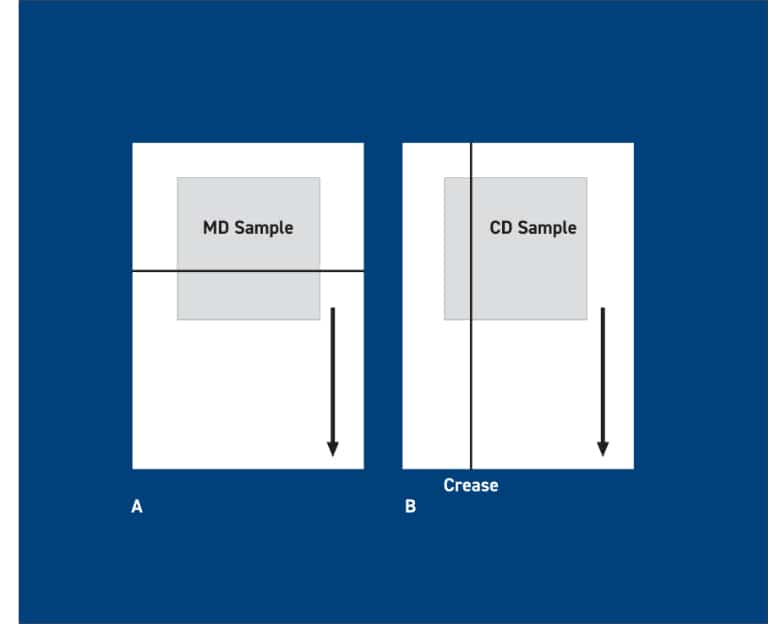

The board direction required for test should run along the 70mm length of the specimen. A number of samples should be tested in each direction. It is recommended that you test MD and CD separately to get accurate results and a crease to board

stiffness ratio.

The size of a standard BS6965 crease sample is 38x38mm with the crease line 13mm in from one edge. The CBT1 instrument is designed to test crease samples of the above size only.

The diagram illustrates MD and CD samples with creases across them, as will be required for crease stiffness testing.

The Hanatek CBT1 tester automatically calculates the Crease/Board stiffness ratio for quick and easy analysis of results.

Measurements made using the CBT1 can be exported to a USB stick via interface software. The data can be transferred to the USB stick. All measured and calculated parameters are exported in .csv file format, as shown below:

Using a custom data cable and pre-programmed label printer the results from the CBT1 instrument can be sent directly to a label printer.

Sample preparation is easy with the Hanatek universal sample cutter.

Prepare crease and stiffness samples.

| Standard | Application | Details |

|---|---|---|

| BS 6965 | Creasing properties of carton board | Method for determination of crease recovery (spring back) of 90° fold |

| BS 3748 | Carton board | Method for determination of resistance to bending of paper and board |

| TAPPI T556 (15" Only) | Paper and board | Bending resistance of paper and paper board by single-point bending method |

| BS ISO 2493 1:2010 | Paper and board | Determination of bending resistance |

| SCAN P29 | Paper and board | Bending resistance |

| PMI 068 | Philip Morris | Determination of the spring-back force of packaging materials |

| Instrument Information | ||

|---|---|---|

| Resolution | 0.5g | |

| Accuracy | 0.1g | |

| Range | 0 - 450gf | |

| Certificate | UKAS traceable calibration certificate | |

| Power | 110/240v 50/60Hz | |

| Dimension & Weights | ||

|---|---|---|

| Dimensions | 230mm (H) x 175mm (W) x 250mm (D) | |

| Instrument Weight | 7.6kg | |

| Packed Weight | 10kg | |

| Commodity Code | 9024 8000 | |

| Order Codes | ||

|---|---|---|

| Instrument | HAN-A9011CBT1.2 | |

| Printer | RL-B-PRINTER/2 | |

| Rounded Jaw | HAN-A-CBTRNDJAW | |

| Dedicated Crease & Board Sample Cutter | HAN-B9100SAMPLE | |

| Universal Sample Cutter Crease & Board to BS6965 & ISO2493 | RL-A80-001 | |

Free extended 2 year warranty: Requires registration at www.rhopointinstruments.com/help-services/forms-feedback/instrument-registration/ within 28 days of purchase. Without registration, 1 year standard warranty applies.

Fast and economic service via our global network of accredited calibration and service centres. Please visit www.rhopointinstruments.com/help-services/calibration-servicing/ for detailed information.

Gloss is an aspect of the visual perception of objects that is as important as colour when considering the psychological impact of products on a

Identify the surface that you wish to measure. Is it a flat surface? If so, it can be measured with a traditonal glossmeter. Curved surfaces

RSpec is the peak reflectance measured over a very narrow angular band in the specular direction (+/-) 0.0991º. RSpec is very sensitive to any texture

Please note, this is NOT a quotation, just a confirmation of the price when purchased in the UK exclusive of VAT/duties